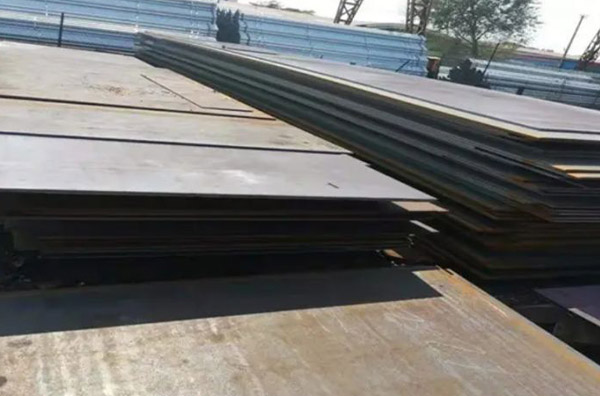

Supply OEM/ODM Wear Blade for Nm400 Nm450 Nm500 Steel Plates

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Supply OEM/ODM Wear Blade for Nm400 Nm450 Nm500 Steel Plates, We warmly welcome close friends from all walks of daily life to seek mutual cooperation and build a more excellent and splendid tomorrow.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Nm500 and High Hardness Prime, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Be sure to feel free to contact us for more information, we assure you of our best attention at all times.

The wear-resistant layer of the alloy is mainly chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are also added. The carbides in the metallographic structure are fibrous distribution, and the fiber direction is perpendicular to the surface. The micro hardness of carbide can reach above hv1700-2000, and the surface hardness can reach HRC58-62. Alloy carbides have strong stability at high temperature, maintain high hardness, and have good oxidation resistance. They can be used normally under 500 ℃.

The wear-resistant layer has narrow channels (2.5-3.5mm), wide channels (8-12mm), curves (s, w), etc; It is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium, nickel and boron are also added. The carbides in the metallographic structure are distributed in fibrous form, and the fiber direction is perpendicular to the surface. The carbide content is 40-60%, the microhardness can reach above hv1700, and the surface hardness can reach HRC58-62.

The wear-resistant steel plate alloy wear-resistant layer and the substrate are metallurgically bonded. Through special equipment and automatic welding process, the high hardness self protective alloy welding wire is uniformly welded on the substrate, and the composite layers are one to two or even multiple layers. During the composite process, uniform transverse cracks appear due to different alloy shrinkage ratios, which is the remarkable feature of wear-resistant steel plate.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Supply OEM/ODM Wear Blade for Nm400 Nm450 Nm500 Steel Plates, We warmly welcome close friends from all walks of daily life to seek mutual cooperation and build a more excellent and splendid tomorrow.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Supply OEM/ODM Wear Blade for Nm400 Nm450 Nm500 Steel Plates, We warmly welcome close friends from all walks of daily life to seek mutual cooperation and build a more excellent and splendid tomorrow.

Supply OEM/ODM China Nm500 and High Hardness Prime, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Be sure to feel free to contact us for more information, we assure you of our best attention at all times.