Astm A106b High precision cold rolled seamless steel pipe

High-precision cold-drawn precision steel pipe is a new type of steel pipe, whose main feature is high precision. Usually two-roller mill and three-roller mill production of two production processes, three-roller mill production of cold rolled seamless steel tube precision is higher, can be controlled within a few silk, but the price is relatively high.The promotion of high-precision cold-drawn precision steel tubes to save steel, improve processing efficiency, save energy The so-called high-precision cold-drawn seamless steel tube refers to the internal and external dimensional accuracy (tolerance range) is strict, internal and external surface finish, roundness, straightness, can greatly save machining hours, improve material utilization, while helping to improve product quality.

The main cold processing methods of steel pipe are cold drawing and cold rolling method. In recent years, with the development of science and technology, and the development of a cold spinning method, with this method can produce large diameter, high-precision cold-rolled tubes and cold-rolled tubes with variable cross-section. Cold processing of steel pipe raw materials can be hot-rolled seamless steel pipe can also be welded pipe. The common feature of the cold processing method of steel pipe is the high dimensional accuracy, good surface roughness, can produce very thin (up to 0.05 ~ 0.01mm) thin-walled tubes and very fine (diameter up to 0.3 ~ 0.1 mm) capillary tubes.Seamless steel pipes are pipes with hollow cross-section, which are used in large quantities as pipelines for transporting fluids, such as pipelines for transporting oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, steel pipe is lighter in weight when the bending and torsional strength is the same, and is an economic cross-sectional steel, which is widely used in pipeline engineering.

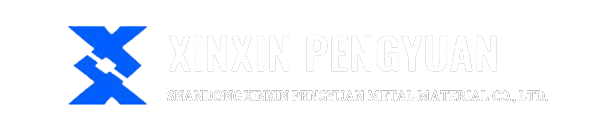

Production :ProcessRound tube blank→heating→piercing→three-roller skew rolling, continuous rolling or extrusion→tube removal→sizing (or reducing)→cooling→straightening→hydrostatic test (or flaw detection)→marking→storage seamless steel pipe It is made of steel ingots or solid tube blanks through perforation to make capillary tubes, and then hot-rolled, cold-rolled or cold-drawn.

1.Structural seamless pipe

(Seamless steel pipes for the manufacture of pipes, vessels, equipment, fittings and mechanical structures)

2.Seamless pipe for fluid transfer

(Pipes used for transporting fluids are pipes for transporting oil, natural gas, gas, water and certain solid materials.)

3.Seamless tube for boiler.

4. Conveying pipeline: Mainly used for conveying water, oil and gas.

5. Line pipe: Mainly used for line protection

6.Auto parts, hydraulic steel pipes

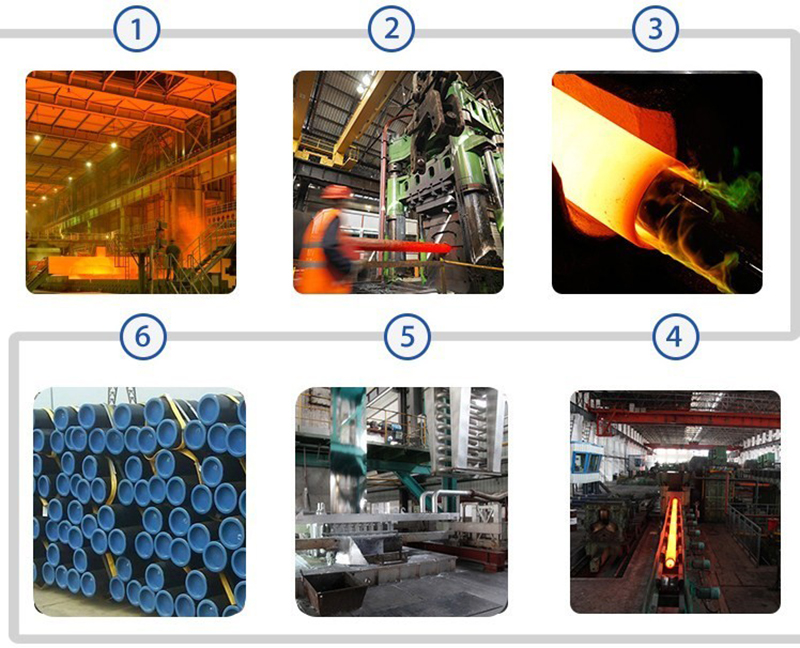

1. Why you choose us ?

Our company has been 12 years. We control the quality of the products very strictly, there are special people for the quality.

If you got lower price from other supplier ,we will pay back twice to customers about the higher price.

2. How long is your delivery time?

According to the quantity.Generally within 2-7 days if in stock.And 15-20 days if not in stock.

3. What is your payment terms?

A: By T/T 30% in advance ,and 70% before delivery.

B:100% L/C at sight.

C:By T/T 30% in advance,and 70% L/C at sight.

4. Do you provide samples ? Is it free?

Yes, we offer the sample for free but do not pay for the cost of freight.

5. What if the customer is not satisfied?

If there is a problem with the product,we take full responsibility.